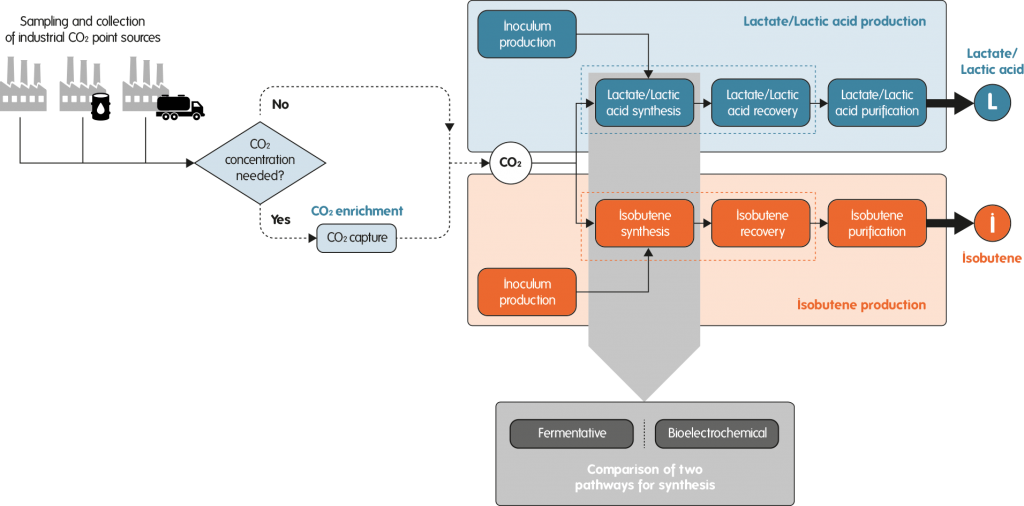

Objectives

BioRECO2VER will reach this through the following specific objectives:

- Development and application of robust enzymes for efficient CO2 capture from industrial point sources by combining enzymatic absorption with ionic liquid-amine blends

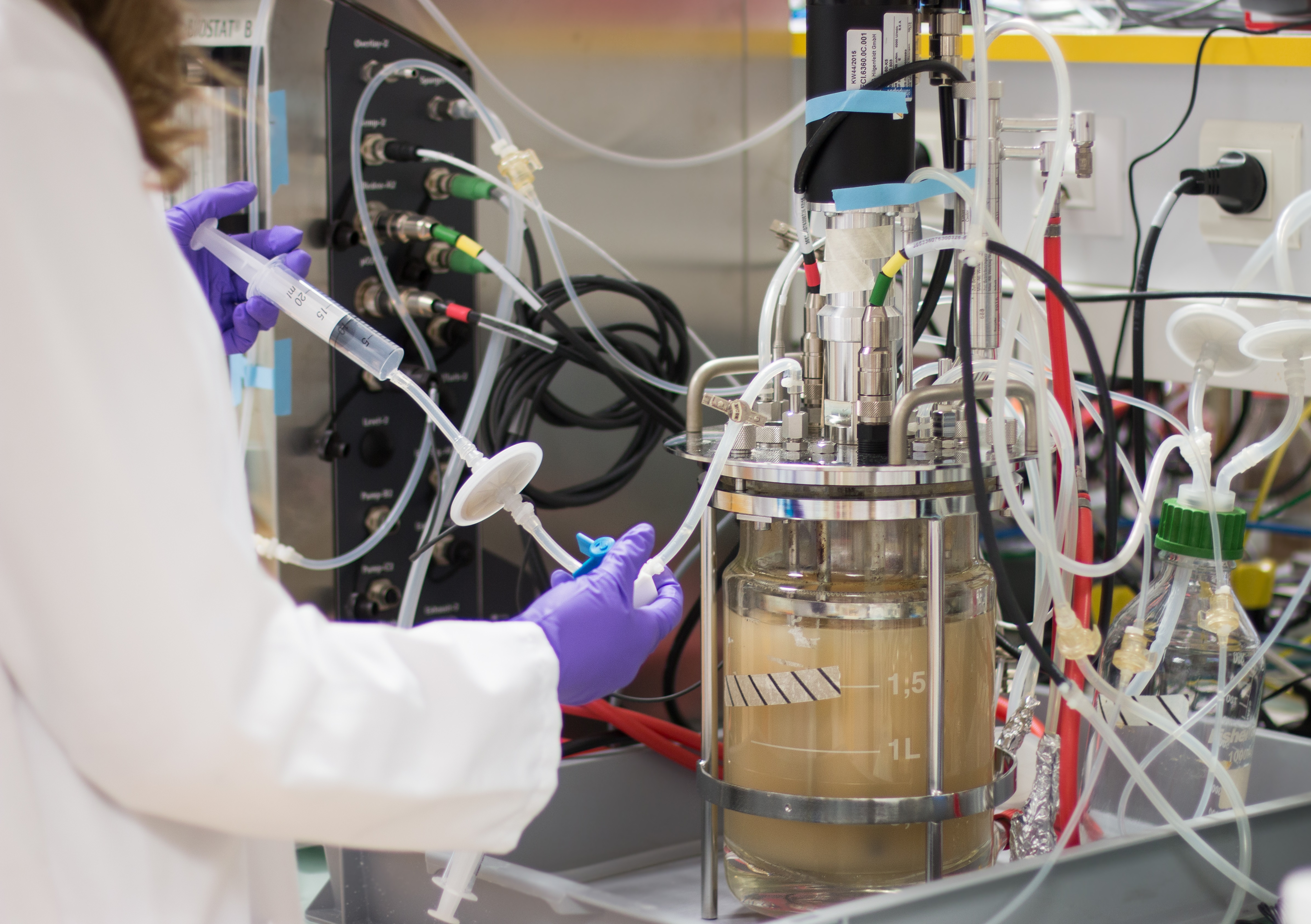

- Development of three different microbial platforms for CO2 conversion into platform chemicals using carbon-free energy supply

- Development of novel fermenter designs to increase fermentation efficiency and optimize process conditions

- Development of bioelectrochemical systems that use in situ generated H2 and renewable electricity as the energy source

- Validation of the most promising isobutene and lactate production route at technology readiness level 5 on real off gases

- Modelling and optimization of the modular technology train

- Provide sustainability assessment and proof of socio-economic and industrial feasibility